This past weekend I decided to put together one of these circuits with a bypass switch that would allow me to disconnect the resistive bridge. With this type of device you can not leave the circuit in line and you must use low power as the resistors, at least the ones I put in are low wattage. Mine were parallel 150 ohm 1/4 watt resistors. This gives me a resistive bridge based on 75 ohms. I chose this since this is the impedance of the feed line I use for my HF station (RG6).

I built this circuit into (You guessed it!) an altoids tin:

|

| http://qrpkits.com/images/swr_ind1.jpg |

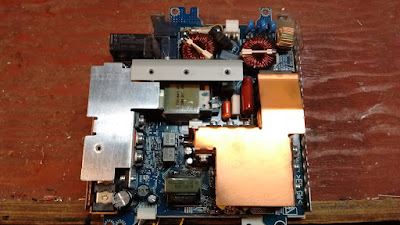

Below are some images of the build:

|

| AC9LF |

|

| AC9LF |

|

| AC9LF |

|

| AC9LF |

|

| AC9LF |

The switch is a simple toggle switch from an old PC power supply. This allows me to bypass the resistive bridge while still leaving the device connected. This speeds up the process of changing frequency and "retuning" my random wire.

The auto transformer is on a toroid core. This steps up the voltage and allows the LED to light up even at smaller bridge imbalances.

Now, the toroid core I used for the auto transformer was pulled more or less at random from my junk bin. As luck would have it, it actually had a part number listed on it. I looked it up after I built it. It is a powder core from "Magnetics" with a part number: 55848A2. From technical data list on the manufacturers web site this core is really only good to 2MHz. Beyond that the permeability degrades by about 5% every 2MHz. With some testing this weekend it proved useful up to about 20meters. I tried it on 21MHz but the non-lit area on my tuner was pretty wide.

Let me explain how I tested this. I have a L-match attached to an end fed wire. This device is in line between the coax from the radio and the L-match network. I would supply a 1 or 2 watt carrier at the frequency of interest into the setup. I would then adjust the L-match while watching the LED. I would get a very good dim led (almost extinguished) on 40 meters (7.2MHz) and 20 meters (14.2MHz). After checking actual SWR at the radio this presented itself as slightly less then 1.5:1 on a 50ohm SWR meter. A very good result!

My tuner allows matching up to about 21MHz, I tried this but the area that was not lit by the LED on the tuner was pretty wide. Indicating that I will need a bit more power to the device at higher frequencies.

For a good write up please see the link in the SWR meter I posted a long while back. I will try and post a video of this cool little thing in action at some point.

I am pretty happy with this solution as it was dirt cheap, works fast and is very effective. It can be improved on with a better core and some tighter wire routing.

73,

AC9LF